Improved

Method for Measuring and Assessing Reticle Pinhole Defects for the 100nm

Lithography Node

Darren Taylor

Photronics, Allen TX 75013

Anthony Vacca, Larry Zurbrick

KLA-Tencor, 160 Rio Robles, San Jose, CA 95161

ABSTRACT

With the approach of the

100nm-lithography node, an accurate and reliable method of measuring reticle

pinhole defects becomes necessary to assess the capabilities of high-end

reticle inspection equipment. The current measurement method of programmed

defect pinholes consists of using a SEM.

While this method is repeatable, it does not reliably represent the true

nature of a pinhole.

Earlier studies have suggested that since the SEM images only a top down view of the pinhole, the measurement does not accurately account for edge wall angle and partial filling which both reduce pinhole transmission and subsequent printability. Since wafer lithography and reticle inspection tools use transmitted illumination, pinhole detection performance based on SEM measurements is often erroneous.

In this study, a pinhole test

reticle was manufactured to further characterize the capabilities of a

transmission method to measure pinholes.

Keywords: Inspection, Pinhole, Printability

1.

PROBLEM DEFINITION

Because of the inability to reliably manufacture and

measure programmed pinhole

defects on test masks,

some reticle inspection tool vendors have stoppedshied away from

setting a specification on these types of defects. This has left a hole in

setting specifications from the customer of the mask houses.

From 1979 to the present, optical shearing microscopes were used to

measure these defects. The resulting measurements were used in multiple

printability studies in the industry. This method was adequate when the size of

the defects were relatively large, however, issues began to arise when the when

the defects fell below 500nm. The repeatability of the measurements became poor

below 500nm and very poor below 200nm. In 2000 KLA-Tencor migrated to using a

KLA-Tencor 8100XPR CD-SEM to measure the defects. This was done primarily for a

high repeatability. The sizing method is the inscribed circle method. This

involves placing a circle inside the defect and reporting the size of the

defect. This methodology was chosen due to thebecause it has pretty

good correlation back to the historical optical sizing1..

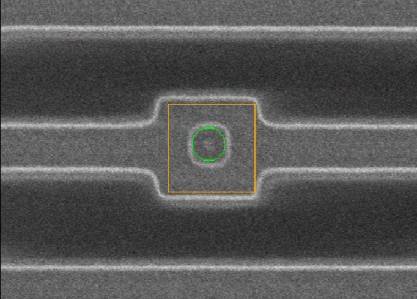

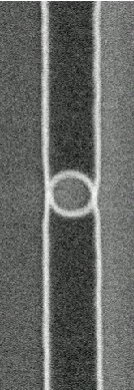

While SEM measurement are highly repeatable there

are issues with this type of measurement. It cannot take into account poor

sidewall or the presence of debris in the bottom of the pinhole. An example of

this is shown in Iimage

1.

Image 1.

CD-SEM Circle

Inscribed Methodology

The green circle is where the measurement was taken.

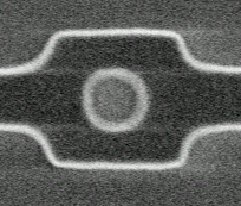

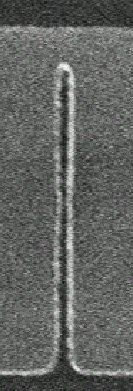

As shown in the image there are very poor sidewalls on the defect. Image 2

shows an example of a "good" defect. This defect has a relatively

high sidewall angle and is completely cleared.

Image 2.

Example of a

"good" pinhole

As the test mask geometry and defect sizes shrink s, and

therefore the defects present, have become increasingly aggressive it

has become necessary to find a new measurement protocol to overcome the issues

seen with the SEM measurements. Several methods were investigated such as probe

type metrology, SEM improvements and transmission based metrology. There are

issues associated with each of these. Probe type metrology is interesting but

the size of the tip approaches or is larger than the defect of interest. SEM

metrology could be improved to capture a better point in the sidewall, however,

it does not address the issue of foreign material in the defect. Transmission

based metrology appears to be the most comprehensive of the three and it moreis closely resembles r to

the actual function of the mask in optical lithography.

Two transmission based measurement tools were

investigated in this, an ongoingthis ongoing study of

the issue, the KLA-Tencor Defect Energy Meter and the AVIÔ Flux-Area Measurement tool. The KLA-Tencor DEM is an engineering mode

tool that uses images from an SLF27 inspection tool to measure the defects. A special noncommercial extraction program was written

that enabled the The AVI tool to uses the same images. but obtains them from a

results file. Both measurement techniques were shown to be

repeatable within a single tool and from tool to tool in an earlier study on

this problem2..

The decision was made to use the AVI tool primarily

because it has the ability to create a reference within the defect image and

the KLA-Tencor DEM tool needs a separate reference image. KLA-Tencor has the

ability to capture images of the defects manually on the SLF27, however, only the

defect image is captured, the reference image is not fully aligned which is

necessary for the needed by the DEM to functionis not

stored.

2.

EXPERIMENT

A programmed defect test mask based on the

KLA-Tencor UTM was built using a 50KeV-lithography tool. The plate was designed

for the 100nm node. The main feature size was 400nm and the defects were in

increments of 20nm. The basis for the test plate was the KLA-Tencor UTM, this

is the mask design that

KLA-Tencor intends to use for setting the detection rate specifications on the 5XX generation tool.

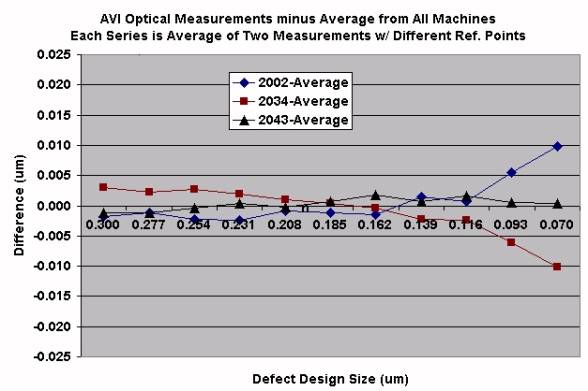

This test mask was inspectedran multiple

times on several KLA-Tencor SLF27 inspection tools and measurements made usingon the AVI tool

on the individual runs. Chart 1 shows the repeatability of the AVI pinhole measurements from system to

system. The X axis shows the average defect size measured with the AVI software

while the X axis shows the variation from the average for each individual

system. The data show less than ±3nm variation all the way down to

the 116nm sized pinhole.

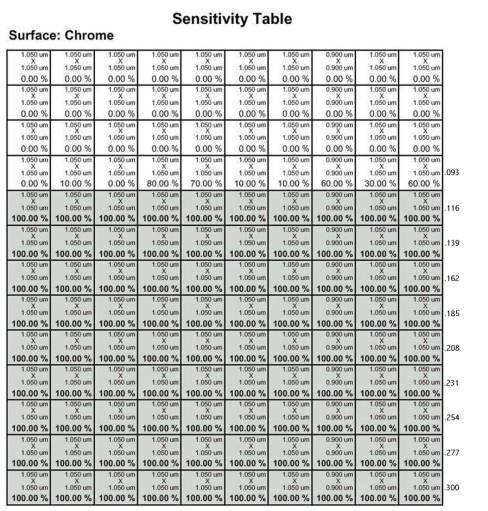

Sensitivity measurements were taken from the

inspection tools and the results are shown in image 5. The gray area in the

sensitivity chart represents 100% capture rate. The individual boxes show the

actual capture rate for that particular defect.

Chart 1Image 3.

AVI System to System Measurement

Repeatability

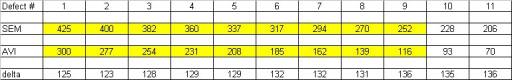

Chart 2 shows the relationship

between the AVI measured sizes and the CD-SEM sizes along with the delta

between them. The delta has a range of 13nm. The yellow bar in the chart shows

the 100% capture point for the SLF27 tool.

Chart 2Image 4.

SEM vs AVI measurements

Image 4 shows the relationship between the AVI

measured sizes and the CD-SEM sizes along with the delta between them. The

delta has a range of 13nm. The yellow bar in the chart shows the 100% capture

point for the SLF27 tool.

Sensitivity measurements were taken from numerous

inspection tools and the results from one system are shown in Chart 3. The gray area in the

sensitivity chart represents 100% capture rate. The individual boxes show the

actual capture rate for that particular defect. The average defect sizes as measured by

the AVI are shown along

the right side vertical axis

Chart 3Image 5.

SLF Pinhole

Sensitivity from Test Mask

3.

PRINTABILITY

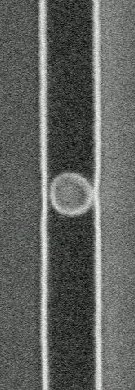

In earlier phases of this study printability was

performed to get a sense of how transmission measurements compared to

printability. A test mask designed for the 130nm node (520nm lines) was printed

with aggressive low k1 lithography

(~ .42).

Defect 12 Defect

12-wafer Defect 11 Defect 11-wafer

Images 36 through 69.

Printed Images

for 130nm node

Images 36 through 69 show two consecutive defects on a

programmed defect mask. There are two pair of images, one SEM image of the mask

and the other is the SEM image of the printed wafer. The SEM circle inscribed

method measurement on defect 12 was 215nm and the SEM measurement for defect 11

was 212nm. The AVI measurements for the same defects were 183nm and 114nm

respectively. As shown in on the wafer images, defect 12 on the mask printed on

the wafer causing the line to pinch. Defect 11 on the other hand did not print

although the SEM measured only 3nm difference between them. The AVI measurement

showed a difference of 69nm, which would be in better agreement with the

printing results.

In the case of isolated pinholes the largest pinhole

on the mask, which measured 279nm by SEM and 155nm by energy measurement, did

not print.

The printability results suggest that the capture

rate of the KLA-Tencor SLF27 tool is well below the printing threshold. The SLF

captured the defects in the 116nm range 100% of the time. It also shows that the

repeatability of the AVI tool is stable well below printing levels.

4.

SUMMARY

Large strides have been made in overcoming the obstaclesability in to repeatablebly measurement of small programmed

pinhole reticle

defects. The AVI transmission

based measurement method, AVI, that was chosen in

this study showed good repeatability on very small defects far below what actually

prints. The KLA-Tencor SLF27 system also demonstrated the ability toshowed a

capture

rate on pinholes far below the printing threshold.

5.

REFERENCES

1 L.

Zurbrick, et al, “Reticle defect size calibration using low-voltage SEM and

pattern recognition techniques for sub-200 nm defects”, Proc. SPIE Vol. 3873,

p.651-658, 19th Annual Symposium on Photomask Technology, F. E.

Abboud; B. J. Grenon; Eds. (1999)

2 D. Taylor, et al, "Improved

Method for Measuring and Assessing Reticle Pinhole Defects", Proc. SPIE

Vol. 4562, p. 272-278, 21st Annual BACUS Symposium on Photomask

Technology, G. T. Dao; B. J. Grenon, Eds. (2002)

L. Zurbrick, et al, “Reticle defect size

calibration using low-voltage SEM and pattern recognition techniques for

sub-200 nm defects”, Proc. SPIE Vol. 3873, p.651-658, 19th Annual

Symposium on Photomask Technology, F. E. Abboud; B. J. Grenon; Eds. (1999)

6.

ACKNOWLEDGEMENTS

Matthew Lassiter, Ben Eynon - Photronics

Mohsen Ahmadian, Ed Longboy, Lantian Wang -

KLA-Tencor

Peter Fiekowsky - AVI

IMEC for graciously printing wafers for this

project